Description

WD Wireless Data Acquisition System

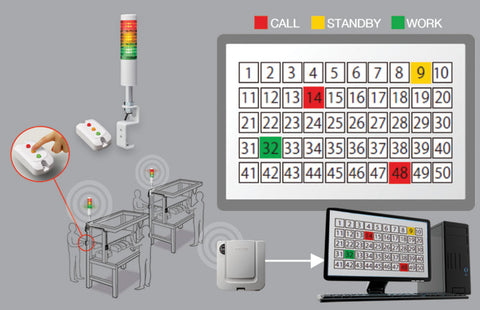

Ideal for Machine & Factory Floor Productivity Data Collection & Analysis

-

1: Signal Tower with WD transmitter installs easily on equipment

-

2: WD receiver acts as a data bridge between transmitters and PCs

-

3: Receive raw equipment data for export to CSV file

Your shop floor is a community of employees, machines, and machine tool processes. The main goal for any shop is to run smoothly, stay productive and avoid downtime, but that is easier said than done. Machine monitoring is the most important task in nearly every machining industry. As floor supervisors/managers, knowing when bottlenecks, downtime, breakage is crucial. With real-time alerts and reports, your floor can avoid major disaster and smart decisions can be made to continue with quality production.

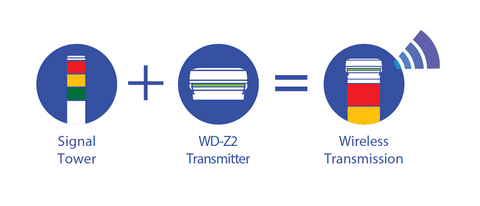

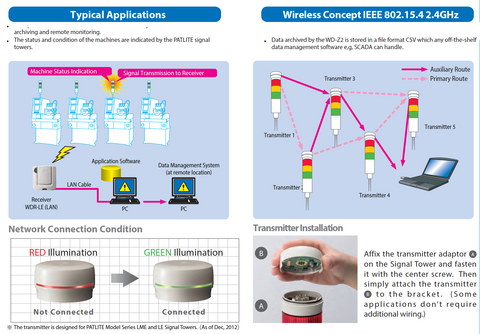

Introducing the NEW Wireless Data Acquistion System from PATLITE! PATLITE wireless add-on modules and receivers make PATLITE Signal Towers capable of sending electrical signals over a wireless network to a data center. Wireless add-on modules and receivers are uniquely practical and economical solution for data acquisition, machine status remote monitoring, and supervisory control of industrial processes. The WD system is a revolutionary, low cost, IIoT add-on allowing Patlite Signal Towers to transmit wireless operational data based on its physical, visual and audible alerts system. Seamlessly acquire and view real-time machine data, irrespective of the age or type of machine, to prompt immediate responses from operators.

Predicting maintenance, identifying bottlenecks and increasing OEE (Overall Equipment Effectiveness) on the factory floor is now simpler than ever. The WD-Z2 is an effective solution for lean manufacturing and visual factory.

CASE STUDY 1

|

BEFORE Production bottlenecks caused by machine down time and uneven production flow are surmounting. To address this issue, employees are creating daily machine reports which are tedious and inaccurate. |

|

AFTER The WD system enables us to monitor out line in real-time, quickly identify bottlenecks and address them. The PATLITE process can also determine the severity of machine issues for more effective predictive maintenance.

|

CASE STUDY 2

|

BEFORE No system in place to remotely monitor machines in real time. Goal is to share productivity among all facilities to improve company wide productivity.. |

|

AFTER The WD system allows monitoring of all lines in multiple locations and in real-time. Workers are able to better understand how their efforts affect the bigger picture improving company wide productivity.

|

CASE STUDY 3

|

BEFORE Maintenance calls from manual assembly stations are only visually displayed on signal towers. When a supervisor is away from a station or site, delays and production bottlenecks occur. |

|

AFTER With the WD installed in workstation, supervisors can now receive email alerts for maintenance calls when away from the site, greatly reducing bottlenecks.

|

Model Specifications

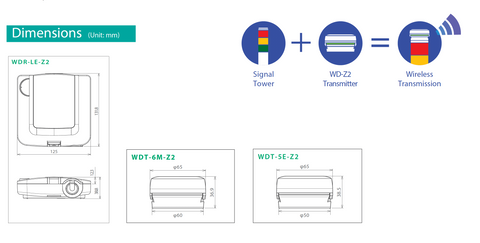

| DIMENSIONS | - H131.8 W125 D38.8mm |

|---|---|

| OPERATING VOLTAGES | - Rated Voltage: DC24V (Non-polar) - Operating voltage Range: DC21.6V to DC26.4V |

| PROTOCOLS | - Description: Stationary Receiver |

| FUNCTIONS | - Operating Temperature Range: -10℃ to 60℃ (No Condensation) - Operating Humidity Range: 85% RH or less(No Condensation) - Storage Temperature Range:-20℃ to 70℃(No Freezing) - Installation: Upright Position(Indoor Only) |

| BODY STYLE | - Mass: 160g |

| BODY COLOR | - Body: Beige |

| CONFORMITY STANDARDS | - FCC - NCC - NBCT - SDPPI - SRRC |